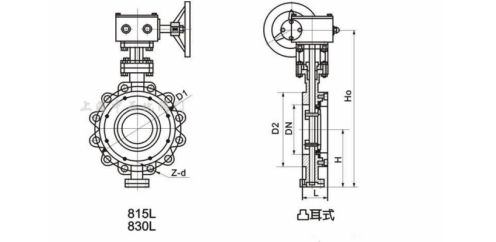

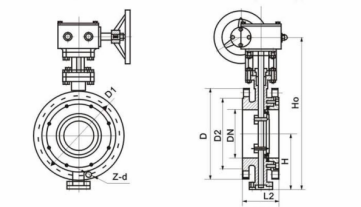

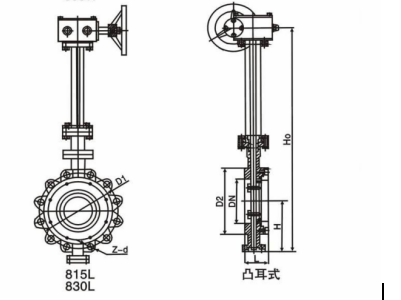

The main structural feature of the 815, 830, series of the folder type butterfly valve and flange three eccentric structure, and main structural features 815, 830L series butterfly valve is the valve body around with protruding ears and designed with screw single flange structure. 815, 830 Series Butterfly valves are widely used in petroleum, chemical and industrial environmental water treatment, high-rise buildings, to the drainage pipe.

Its characteristics: due to the use of the three eccentric structure, sealed reliable performance, ensure that when opening the butterfly plate does not contact the sealing seat, the sealing seat eliminates uneven load, prolong service life, and ensure reliable sealing performance, has the advantages of high temperature, abrasion resistance, corrosion resistance etc..

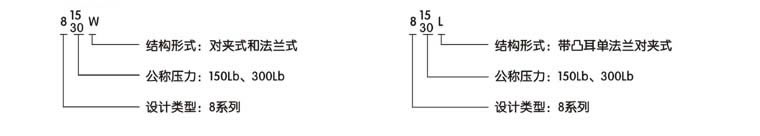

American Standard of clamp, double flange type metal seal butterfly valve / clamp, single flange type fluorine plastic sealing butterfly valve